About Us

In 2010, Vayuvents Private Limited, was founded in Vasai, Mumbai (Maharashtra, India). We are a manufacturer and exporter of various products, including Roof Ventilator Fan, Centrifugal Blower, Axial Fan, Dust Collector, Wet Scrubber, Hot Air Blower, and many more. To satisfy the wide range of needs of our esteemed clients, we offer our produts in variety of specifications. Because we are so concerned about the quality of the given assembly, we only utilize the best raw materials in our manufacturing process. We have also built a cutting-edge infrastructural facility unified with basic facilities and machines that utilize the most cutting-edge technology available.Our Team

A team is the foundation stone of our business. Every specialist we hire is chosen based on their years...Infrastructure

We have built up an enormous infrastructure at our company that is divided into several departments...Quality Assurance

Every production process is closely monitored by our squad of quality controllers. Our product is put...Product Categories Gallery

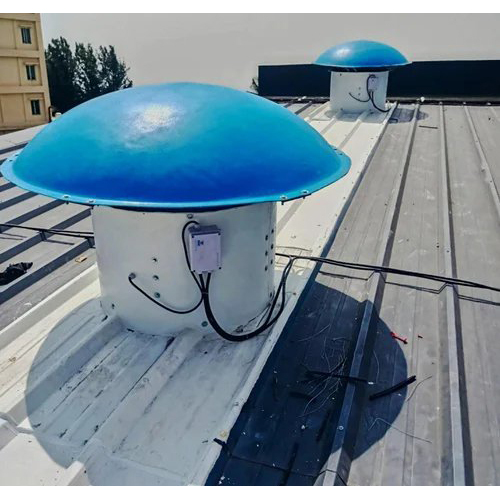

- Ventilation System

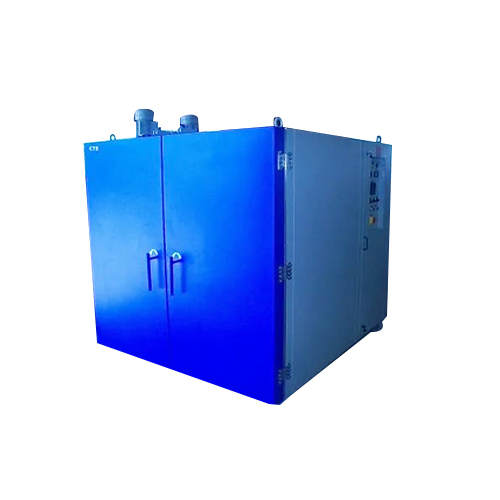

- Heating System

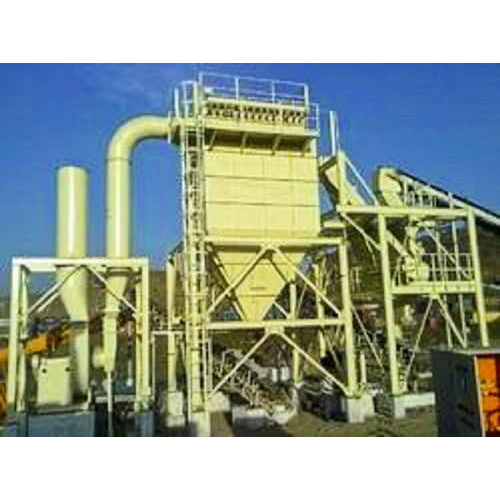

- Pollution Control System

- Daylight Harvesting System

- Dust Suppression System

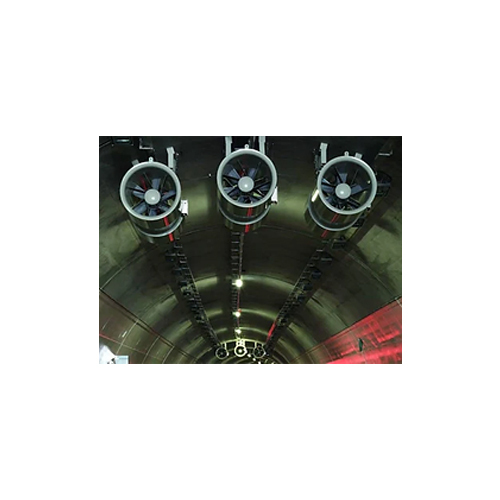

- Underground Ventilation Fan System

- Roof Extractor Fan

- Bug Blower Fan

- PP FRP Blower

- Industrial Exhaust Fans

- Industrial Centrifugal Blower

- Power Driven Roof Ventilation Fan

- Hot Axial Flow Fan

- Dust Collector

- Roof Ventilator

- Roof Ventilation Fan

- Vaneaxial Fans

- Electricity Anti Smog Gun

- Industrial Roof Ventilator

- Motorized Roof Exhaust Fan

- Vaneaxial Flow Fans

- Induced Draft Fan

- Industrial Electric Oven

- Pulsejet Dust Collector

- Packed Bed Scrubber

- Varnished Motor Curing Ovens

- Air Ventilator

- Industrial Ventilation Fan

- Ventilation System

- Ship Deck Axial Flow Fans

- Wall Mounted Fan

- industrial furnaces fume extraction systems

- Roof Top Turbo Ventilator

- Industrial Man Cooler

- Industrial Hot Air Blower

- Tube Axial Flow Fan

- Industrial Blower

- Tube Axial Fans

- Industrial Scrubber

- Industrial Oven

- Motorized Roof Extractor Fan

- Industrial Axial Flow Fan

- Repairs and Maintenance Service

Most Popular Products

A centrifugal blower is a mechanical device that moves air or other gases by using centrifugal force. It increases the speed and volume of an air stream, which is then forced into a specific area.

The blower works by drawing air into the center of a rotating impeller, which has a series of blades. As the impeller spins, the air is accelerated outward toward the impeller's circumference, creating pressure and velocity. This high-pressure, high-velocity air is then expelled from the blower's outlet.

A hot air blower is a device that generates and directs a concentrated stream of high-temperature air. It works by passing air over a heated element, which can be an electric coil or another heating source, before a fan or impeller forces the hot air out. These devices are used in a wide range of industrial and commercial applications for tasks such as:

Drying and curing: Accelerating the drying of coatings, adhesives, and paints.

Plastic manipulation: Welding, shrinking, or shaping plastic materials.

Heat treating: Applying heat to components for manufacturing processes.

Shrink wrapping: Applying heat to shrink plastic films for packaging.

General heating: Providing heat to a specific area or workspace.

Unlike simple air heaters, hot air blowers combine the air source and heating element in a single unit, allowing for precise control over both temperature and airflow.

A tube axial flow fan is a type of industrial fan that moves air in a straight line, parallel to its rotating hub and blades. It is essentially a propeller or disk-type wheel enclosed within a cylindrical housing or duct. This design allows the fan to create a high volume of airflow at a relatively low pressure.

Marine fire dampers are used in air conditioning and ventilation ductwork onboard yachts, merchant ships, navy vessels and offshore rigs to prevent the spread of fire, smoke and gas inside the ductwork. In case of fire, the fire and gas dampers will close automatically, preventing additional oxygen to enter the space to fuel and spread a fire

A bug blower, also known as a drilling rig fan or marine bug blower, is a heavy-duty industrial fan designed for use in hazardous environments, particularly on oil and gas rigs (both onshore and offshore). Its primary purpose is to:

Disperse insects: Its powerful airflow keeps flying insects away from workers and equipment.

Ventilate: It helps to clear hazardous gases that can accumulate in drilling areas.

Cool: The strong air movement provides a cooling effect for the rig crew in hot environments.

These blowers are built with safety in mind, featuring explosion-proof motors, non-sparking blades, and sturdy construction to withstand the demanding conditions of industrial sites.

A bug blower, also known as a drilling rig fan or marine bug blower, is a heavy-duty industrial fan designed for use in hazardous environments, particularly on oil and gas rigs (both onshore and offshore). Its primary purpose is to:

Disperse insects: Its powerful airflow keeps flying insects away from workers and equipment.

Ventilate: It helps to clear hazardous gases that can accumulate in drilling areas.

Cool: The strong air movement provides a cooling effect for the rig crew in hot environments.

These blowers are built with safety in mind, featuring explosion-proof motors, non-sparking blades, and sturdy construction to withstand the demanding conditions of industrial sites.

Fume extraction prevents health risks, improves productivity and ensure compliance

Ensuring clean air in the welding industry is crucial for preventing serious health risks among welders, enhancing productivity and maintaining compliance with safety standards. Exposure to welding fumes, recognized as a known carcinogen, necessitates safe and compliant working environments to protect welders.

Whether operating a small welding workshop, field welding or a large scale automated factory, Nederman is dedicated to providing fume extraction solutions that meet your specific requirements. Regardless of the welding method employed, be it robotic or manual, effective welding fume extraction is imperative to safeguard welders, sustain productivity, and compliance with rules and regulations.

A dust collector system is an air pollution control technology that removes particulate matter and impurities from the air or gas released by commercial and industrial processes. Its main purpose is to improve air quality and ensure a safe work environment for employees.

A wet fume scrubber is an air pollution control device that uses a liquid, typically water or a chemical solution, to remove pollutants from industrial exhaust streams. It's especially effective for dealing with harmful gases and particulate matter that can't be handled by dry filtration systems

An industrial batch oven is a type of heating chamber used for thermal processing of products in a non-continuous, or "batch," manner. Instead of a conveyor system, items are loaded into the oven all at once, heated for a specified time, and then removed. This makes them ideal for applications with varying product sizes, shapes, and process requirements.

A roof ventilator, or roof vent, is a device installed on the roof of a building to facilitate air circulation. Its primary function is to remove hot, stale, or moist air from the attic or roof space and draw in fresh, cooler air from the outside.

A smoke extraction fan, also known as a smoke exhaust fan, is a critical component of a building's fire safety system. Its primary purpose is to remove smoke, heat, and toxic gases from a building in the event of a fire.

A mushroom ship vent is a type of ventilation system used on marine vessels. It is characterized by its distinctive mushroom-shaped head, which is designed to be installed on the deck. This unique shape allows for efficient airflow while also preventing water, rain, and spray from entering the ship's interior. These vents are crucial for maintaining air quality, preventing moisture buildup, and reducing odors in various compartments, such as cabins, engine rooms, and cargo holds. They can be either fixed or adjustable, with some models featuring a built-in damper to control the amount of airflow

A tunnel fan, often a jet fan or axial fan, is a powerful ventilation device used in tunnels to manage air quality and safety. Its primary purpose is to circulate air, removing pollutants and exhaust fumes from vehicles. This is crucial for maintaining a safe and comfortable environment for drivers and passengers.

An aluminum casting impeller fan is a type of fan with an impeller (the rotating component with blades) that is manufactured using an aluminum casting process. This method of production offers several key benefits, making these fans a popular choice for various industrial and commercial applications.

Our Tools

Manometer, Sound level meter, Anemometer, Temperature measuring device, Vibration meter, etc. are some tools used by our company to carry out everyday tasks.

Our Clients

Patanjali, ARI, JSW, Umang, Indian Oil Limited, etc. Are some key customers served by our company.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese